NSG Group's initiatives to decarbonize and reduce environmental impact

As an energy-intensive and carbon-intensive manufacturing company, tackling climate change is essential for the Group.

Contributing to a decarbonized society through our products and services will help us fulfil our mission to "changing our surroundings, improving our world". We are actively working across social issues such as climate change, contributing to a sustainable society and increasing our corporate value. The Group continues to endorse the Task force on Climate related Financial Disclosures (TCFD), with actions including increasing the intensity and expanding the scope (to include all three emission scopes) of SBTi verified decarbonization targets in May 2022 (original verification in 2019). It has also committed to achieving carbon neutrality by 2050. The implementation of the roadmap to achieve this will lead to a reduction in CO2 emissions and, in turn, to the continued development of sustainable products and the expansion of opportunities related to our business.

*1 SBTi is a partnership between CDP (former Carbon Disclosure Project), UN Global Compact, WRI (World Resources Institute) and WWF (World Wildlife Fund), which helps companies set the science-based goals for reducing GHG emissions to prevent the impact of climate change.

*2 Scope 1: Direct emissions by business operators (Use of fuel in manufacturing processes, etc.)

*3 Scope 2 Location: Indirect emissions by consumption of energy sources (Purchased electricity used in manufacturing processes, etc.)

*4 Scope 3: Value chain emissions including both upstream and downstream of the organization's activities. Because >99.9% of our GHG emissions are CO2, thereafter we only mention CO2

Initiatives to reduce Scope 1 (own emissions)

Our scope 1 emissions were 2.8 million tonnes of CO2 (2.9 million tonnes in 2023). These direct emissions occur from a combination of the combustion of fossil fuels within the manufacturing process and the decomposition of carbonate raw materials in the glass melting process.

We continue to implement a range of technical options to reduce Scope 1 emissions, including:

- Use of alternative fuels: we are actively engaged in technological development initiatives, such as the world's first successful production of float glass using hydrogen energy in September 2021, as well as the successful production of glass using 100% biofuels in February 2022.

- Electric melting of glass: efforts are being made to increase the amount of renewable electricity used as a substitute for fossil fuel in the glass production process. In 2024 the Group announced the intention to implement a project to achieve a step change in the utilization of electricity in float glass furnace operation. This project will represent the highest level ever achieved within the Group for electric melting. The project will be implemented with the support of the German Government. Start date of the operation is now expected in 2026. We are planning to gradually introduce this system to other facilities by 2030, according to the decarbonization roadmap at a global level.

- Substitution of glassmaking raw materials: during the glass melting process, large amounts of carbon dioxide are emitted due to decomposition of CO2 containing raw materials in the furnace, accounting for about 20% of our Scope 1 emissions for glass melting. In order to reduce the carbon dioxide emissions from these raw materials, attempts are being made to replace the carbonates in the material with various oxides: first implemented in 2022, glass production using "Dolime" (CaOMgO) was successfully achieved in a float furnace in Chile; Previous research has shown that, in addition to the CO2 reduction effect derived from the raw materials, there is also an energy reduction effect from using dry lime. The handling of the powder is an issue for the future. Studies continued in 2024 with further trials being developed.

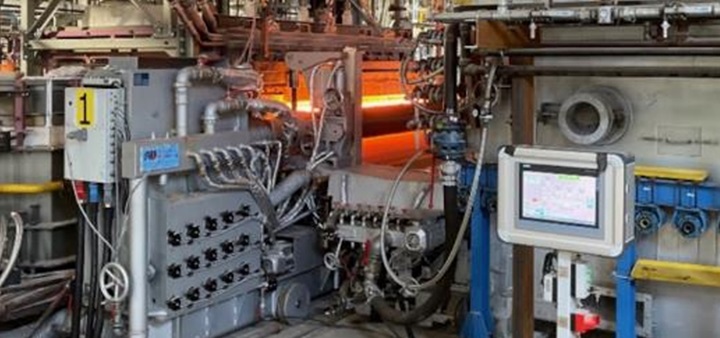

- Carbon capture: the process for capturing CO2 emissions from glass melting furnaces is not compatible with typical CO2 capture processes, so we are working with a process development partner that is likely to be compatible with our needs. In March 2024, we began the first demonstration experiment for carbon capture in the flat glass industry in Europe at our float furnace in the UK.*1 One of C-Capture's carbon capture solvent compatibility units (CCSCUs) has now been deployed at Pilkington UK's float furnace at the Greengate glass manufacturing site in St Helens, part of NSG Group.

- Manufacturing Plant Integration: Another world first was achieved by NSG Group in 2025. This involved the transfer of the rolled glass manufacturing operations onto the Greengate float glass operations site in St. Helens, UK.*2 This transfer involved the installation of a new rolled glass manufacturing line connected to the float furnace. This connection was installed while the float furnace production was maintained. The integration of rolled and float glass operations from one furnace is expected to reduce Scope 1 and 2 CO2 emissions by 15,000 tonnes in absolute terms. Such integration of operations is part of the decarbonization activities for the Group, delivering improvements in the environmental sustainability of products.

Initiatives to reduce Scope 2 (own emissions)

Our Scope 2 emissions (market-based approach) were 0.53 million tonnes of CO2 (0.50 million tonnes in 2023). These indirect emissions occur from the use of purchased electricity & heat.

In response to the medium-term plan announced in 2024, the company set a new sustainability target of increasing the ratio of renewable electricity. This target is to achieve 65% renewable electricity ratio by end of FY2027/3 (MTP phase 1) and 85% renewable electricity ratio by end of FY2030/3 (MTP phase 2). Progress towards this goal continued in 2024, with a YoY improvement in the renewable electricity ratio. Although there were some issues of affordability and availability of viable renewable electricity solutions in several countries where NSG operates, we continued to try to achieve both financial stability and sustainability.

The Group continues to invest in on-site power generation including installing on-site solar power at the Lathom Research Institute in the UK and the Rossford plant in Ohio, USA. Many other solar projects are underway across the Group. The largest individual on-site PV facility at the Ottawa float glass facility was recently commissioned*3. We are also actively introducing power source certification and Power Purchase Agreements (PPA agreements) on a global basis. In March 2024, our Maizuru Plant became the first of our group's domestic plants to sign a PPA contract for renewable electricity generated by solar panels installed on the plant grounds, and installation work began*4. Against a backdrop of global CO2 reduction efforts, there is an increasing demand for green power in the market, and with the risk of rising electricity prices, we are continuing our efforts to find the most economically rational procurement method from among various options on a global level, aiming for stable procurement of renewable energy in the medium to long term.

Initiatives to reduce Scope 3

Scope 3 emissions were verified at 3.71 million tonnes of CO2 in 2024 (3.68 million tonnes in 2023).

In 2024 the decision was taken to recalculate the Scope 3 emissions across NSG Group from 2018 through to 2023. This decision was taken following feedback from various external sources and internal reviews following the establishment of a more robust calculation procedure for Scope 3 emission. The new methodology was endorsed by SBTi. This recalculation has resulted in an increase in the Scope 3 emissions for each year from 2018 to 2023 (in 2024 we already utilized the new calculation methodology).

The revised Scope 3 emissions can be seen in the table below. This demonstrates a YoY improvement in Scope 3 emissions since 2018, with 2024 performance being at 6% reduction in absolute terms compared to 2018.

In 2022, the company launched a Sustainable Supply Chain Committee to examine sustainable supply chains with regard to all factors, including environmental and social aspects. In the course of its activities, it is also working on reducing Scope 3 emissions. In 2024, we held a cross-departmental Scope 3 workshop with the participation of various key members of the company. We have drawn up a company-wide roadmap for achieving our Scope 3 reduction targets for 2030, and in order to achieve this, we recognized the importance of improving our internal data collection system and continuing dialogue with key suppliers. We are working with actual suppliers to obtain emissions data and share best practice alongside various other initiatives.

This supply chain interaction initiative has been recognized once again by the CDP disclosure, with NSG Group maintaining the highest leadership level for supplier engagement assessment 'A' list.