Health and Safety

Our safety programs emphasize the importance of our vision and values, that people are our most important asset and the safety of our employees and the communities in which we operate is a core part of our ethical business philosophy.

Please refer to the "NSG Group Health and Safety Policy".

Safety organization and strategy

The NSG Group Sustainability Director reports to the President and CEO Munehiro Hosonuma.

Monthly safety updates are provided to the Operational Performance Review meetings while more in-depth management reviews are completed every six months with the senior operations team comprising the heads of the four SBUs and the heads of the Group functions.

All injuries at work are regarded as avoidable. We require full reporting of all incidents, no matter how minor, and appropriate investigation to ensure we learn from all such events. The Group has a focused site approach that provides additional support and more regular reviews for sites that have more than a defined number of significant injuries.

Improving our root cause analysis is a fundamental part of the group's improvement strategy, it is only by identification of the underlying causes of accidents and incidents that the group operations will improve in the longer term.

To make these improvements, the NSG Group introduced EcoOnline's new reporting and survey tool, AVA, in 2020. This system will improve functionality in stages. As the next step for AVA, we're getting ready to introduce a behavioural observation and audit system to further support the NABIS program, and we plan to have AVA 2.0 with new features up and running by the end of this fiscal year.

Safety performance FY2025/3

On 29 July 2024, at our Chiba Plant in Japan, a tragic accident occurred in the equipment used to treat exhaust gas from a Float furnace. High-temperature sodium sulphate powder collapsed, burying three employees, one of whom tragically lost their life. We extend our deepest condolences to the family and loved ones of the deceased employee.

In response to this serious workplace accident, the NSG Group has initiated efforts to identify all high-risk operations involving entry into confined spaces, conduct risk assessments, and prepare appropriate risk mitigation measures, including emergency rescue procedures, as part of its contingency response plan.

Furthermore, with the firm resolve to prevent any fatal accidents from occurring again, we have re-examined all high-risk operations. To ensure that all necessary measures and improvements identified for these high-risk areas are implemented without omission or inconsistency, we have created clear guidelines for each operation and commenced efforts to implement equivalent risk reduction activities across all facilities.

Safety activity for vehicles and pedestrians, which began in FY2023/3, have mainly focused on physically separating vehicles and pedestrians and introducing collision avoidance systems such as vehicle-mounted camera systems and TAG systems. We will continue to accelerate the introduction of these measures.

The significant injury rate (SIR) records injuries requiring specialized medical treatment or the injuries where the same work cannot be continued and there is a loss of work, expressed as a rate per 200,000 hours worked. The SIR for FY2025/3 was 0.31, marking a 3% decline from FY2024/3. We will continue to reduce unsafe behaviour by strengthening leadership guidance and communication centered on GEMBA walks*, while prioritizing efforts to enhance education and training for less experienced workers and emphasizing compliance with rules in the FY2026/3.

Additionally, in the second half of the FY25, we have begun installing CCTV cameras high-risk areas and introducing Artificial Intelligence (AI) into existing CCTV system to automatically detect hazardous actions and conditions. This system is already operational and will support employees in executing safe behaviours and leaders in managing the workplace.

*Gemba Walk; Activities of safety patrol by managers to identify and improve safety issues in workplace through communications between managers and operators.

NSG Group's initiatives for safety

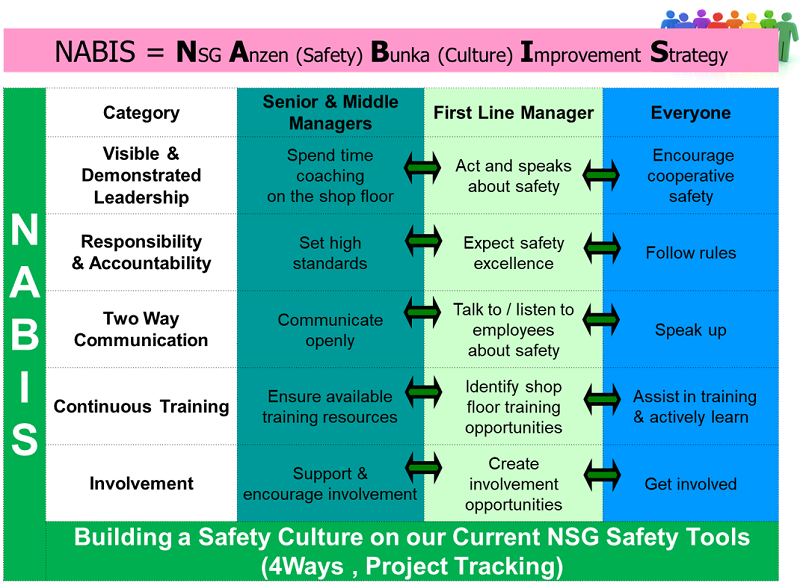

NSG Group is continuing to drive proactive safety through a measure called NABIS (NSG Anzen Bunka Improvement Strategy) this process has three main areas reflecting our focus points. NABIS consists of five components: Leadership, Responsibility and Accountability, Communication, Training, and Involvement.

-

Leadership

Leaders at all levels of the business are being asked to make their leadership visible and actionable by, for example, using processes such as GEMBA walks to spend more time talking with field leaders and employees about various improvement opportunities.

To further improve the GEMBA-walk process the group is starting to measure the numbers of GEMBA walks completed and reviewing information derived from the process.

We continue to ensure all our leaders assess themselves against our 10 key leadership behaviors, asking them to lead by example and to review their teams against a set of principles, such as never walking past an unsafe act without talking to the individual.

-

Responsibility and accountability

Leadership teams must ensure that people follow the procedures and safety rules for the tasks we ask them to complete. This area continues to ask leaders to consistently review the ability of their colleagues to competently complete the tasks. This also forms part of the GEMBA process in that leaders observe how individuals are working and identify learning opportunities. We also promote the identification of risks and quantitative assessment of risks in all areas of our business.

-

Communication

Improving the way in which we communicate safety through regular opportunities for two-way briefings and more formal safety meetings with employees and their representatives is an important way of providing clear information on both reactive and proactive safety initiatives. Leadership teams are required to ensure this communication process is effective.

In FY2023/3 the NSG Group will introduce a safety culture survey to be completed at its larger manufacturing facilities in Architectural, Automotive and Creative Technology and have implemented second survey in February 2025. This survey will provide leadership teams with feedback on the current level of safety culture in their plants; in addition, it will also allow employees to provide anonymous comments and suggestions to help plants improve.

In certain regions and countries, the group has formal communication and discussion with employees' unions, for example, in Europe the business holds a forum with unions from the Germany, Spain, Italy, Finland the UK etc. this is held on a 6 monthly basis.

-

Training

Ensuring our employees have the tools and ability to deliver our commitments in a safe and ethical manner requires a continual review and update on training needs and competences. Leaders are required through NABIS to ensure that, from a safety point of view, people have the correct knowledge to complete this task.

-

Involvement

Asking people to become proactively involved in safety in our plants is part of the leader's responsibility and in NABIS we ask our leadership teams to look for opportunities to involve teams and individuals in safety projects, with the implementation of suggestion schemes and participation in Kaizen processes across many of our larger manufacturing plant being a part of this process.

In addition, as an opportunity of Involvement for all employees, NSG Group Safety Day is held every October, a day for all Group employees to think about safety. Last year, related events were held on 10th October at sites around the world.

Last year's common theme was 'Engagement (returning to basics)'. In order to reaffirm our commitment to mutual enlightenment, which is our desired safety culture, safety activities were carried out with the participation of all employees at each of our business sites.

Gelsenkirchen, Germany

Itami, Japan

NABIS requires our leadership teams to manage our high-risk activities.

As mentioned above, the NSG Group creates standard guidelines for all high-risk work to ensure a consistent level of commitment across the entire group. In addition, we continue to focus on the following high-risk work that we have already been working on.

- Working where there is a risk of falling

- Vehicle and pedestrian safety

- Machinery safety: guarding, FASS* and complete isolation

- Contractor control, including permits

- Materials handling: moving glass, load security, grabs, trolleys and pallets

- Driving in connection with work

*FASS (Frequent Access Safety System) is a system that partially stops equipment by interlocking, etc.

The Groups commitment to NABIS for larger sites has been reinforced around the globe with a verification process. This ensures Health and Safety professionals within the group review the self-assessment scores submitted by the larger operational plants. This process forms part of plant leadership team's performance reviews.

Moving safety to the next level

The safety strategy within the group remains, it will continue to focus on improving the effectiveness of our safety tools and programs. The goal is to achieve a high level of safety culture by continuing to focus on NABIS.

At the same time, the following priority measures will promote the reduction of potential high risks on site:

- Further improvements will be made regarding vehicle and pedestrian safety, building on the risk identification carried out to date. Particular focus will be given to the increased implementation of TAG and camera systems.

- Focusing on Very High Potential Severity (VHPS) events from the Significant Injury (SI) that have occurred, the system completes risk reduction measures that are common to all sites in the Group.

- The introduction of CCTV cameras and AI supports the identification of on-site risks, unsafe conditions, and behaviors, enabling risk reduction activities and the reduction of unsafe behaviours. The CCTV camera + AI system has already begun priority implementation starting with high-risk sites. We will accelerate progress further and proceed with company-wide deployment.

*CCTV cameras + AI: AI analyses CCTV camera images in real time, automatically detects and records unsafe behaviour that has been set in advance.

Significant Injury (SI), Lost Time Injury (LTI) and Facilities