Consistent Customer Satisfaction

As a foundation for achieving consistent customer satisfaction the NSG Group operates with management systems certified according to ISO9001: 2015 and IATF 16949 in all Strategic Business Units.

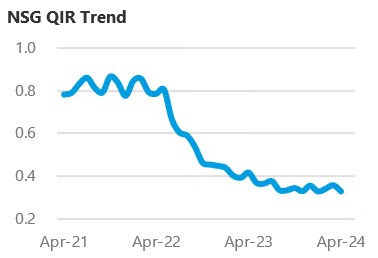

The Group Quality Incident Rate (QIR*) was stable in 2024 and the medium term target remains to achieve further reductions in QIR and zero major quality spikes by FY2030/3.

Building on the foundation of our Pass Only Good Glass initiative a continuous improvement (CI) philosophy helps NSG to deliver customer satisfaction and in 2024 an internal 7-step process was defined to standardize the approach to continuous improvement in all areas of manufacturing. This provides detailed guidance on both reactive problems solving and the proactive identification and harnessing of opportunities.

A training package for all process engineers has been provided to supplement the effective application of the procedure. As part of the Quality Improvement strategy the CI cycle together with Lesson Learnt process will make our production processes more robust and drive a reduction in costs.

*QIR is a measure of the occurrence of quality incidents affecting external customers with financial impact > JPY 0.01 bn as a ratio of sales. Major quality incidents are those with cost > JPY 1.0 bn.

Quality Culture

A strong culture ensures informed and engaged employees, who actively participate in improving performance. NSG is running a number of initiatives to reach out to employees through direct communication of information to all levels of the organization. Alongside the Global Quality Week held each year, a new Manufacturing Excellence Newsletter has been introduced. This internal newsletter has a large number of global followers and is used to inform employees about Group, regional or local initiatives in the NSG manufacturing world.