Waste and Circular Economy

The NSG Group is fully committed to reducing adverse environmental impact by maximizing the reuse, recycling or recovery of resources and minimizing the production of waste involved in glass manufacture, processing, packaging, and delivery.

Please refer to the "NSG Group Sustainability Policy" and the "NSG Group Environment Policy".

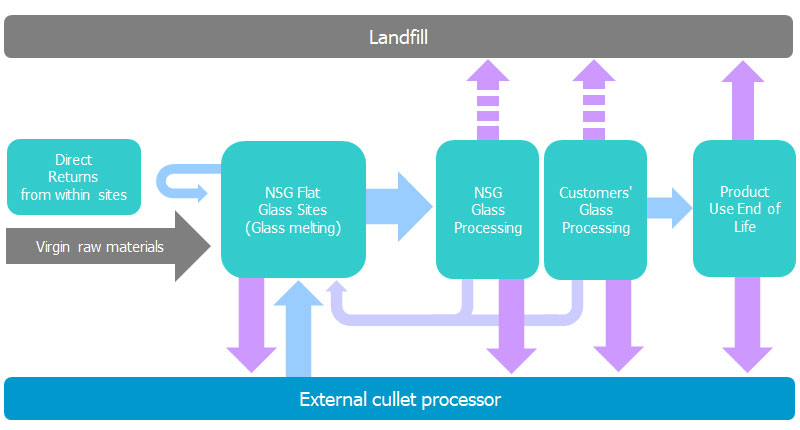

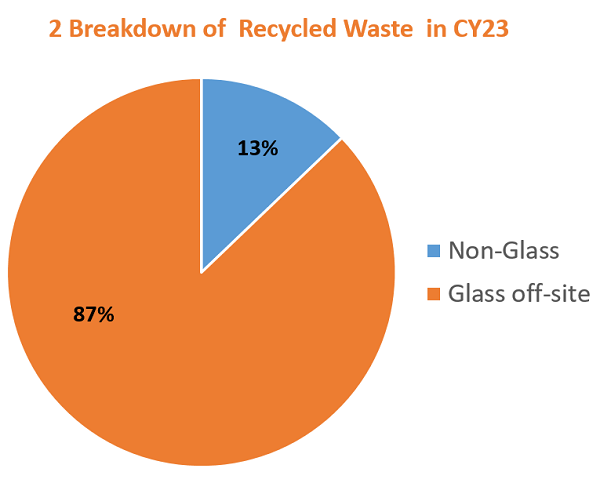

Re-use and Recycling of Glass

The glass manufacturing process itself produces very little waste material. All trimmed glass from the manufacturing processes of raw float glass plates is reused in the melting process and replaces virgin raw material. Cullet and rejected parts from further glass processing for Automotive or Architectural Glazing parts are reused or recycled at the NSG Group glass melting process or given to external glass recycling partners to be used in other glass melting sectors. Re-melting of glass cullet significantly helps to reduce energy consumption and related CO2 emissions. Remelting of one tonne of cullet avoids approximately 400-700 kg of CO2 emission.

In light of recent societal trends towards the circular economy, we set a new target for glass recycling last year. The objective is to increase the glass cullet ratio by 3 % points vs FY2019/3 by the end of FY2027/3. For FY2025/3, the glass cullet ratio increased by 0.6 % points vs FY2019/3. We are actively pursuing initiatives, such as collaborating with customers to recycle glass from downstream processing and End-of Life products. For details on these efforts, please also refer to 'Sustainability and Products'.

■ Cullet flow

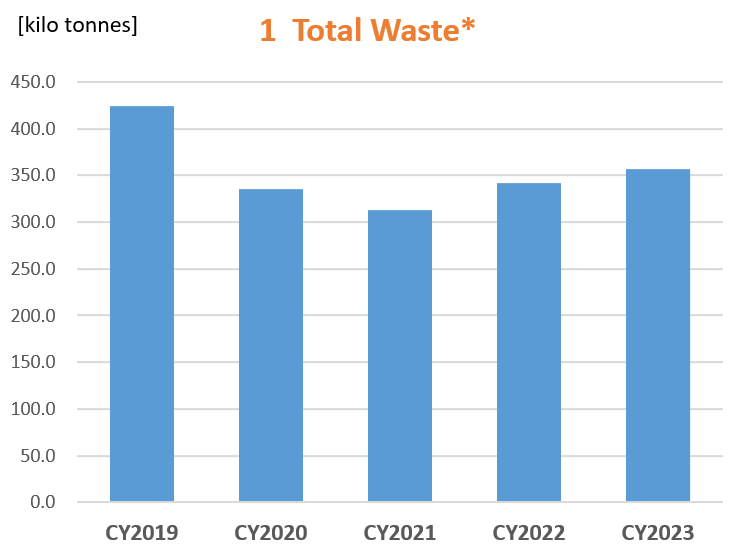

Compiling and monitoring of waste data

In 2019 the NSG Group has implemented a new and more sophisticated Environmental Reporting and Analysis database. All sites are reporting their waste data into this central database for further aggregation, analysis and monitoring on corporate and site level. If not monitored internally (E. g. re-used internal cullet) - the waste quantity data is based on waste transfer notes.

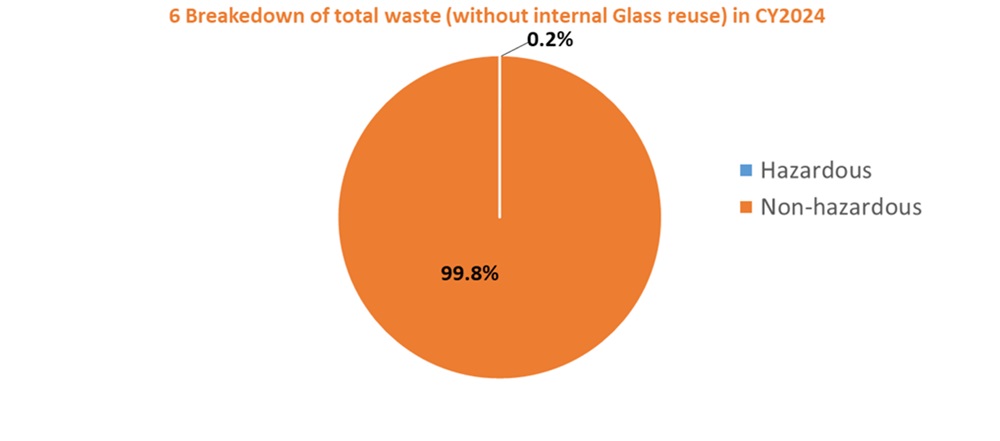

* Total Waste does not include Reused Waste (on-site Reused Glass), which is internal process.

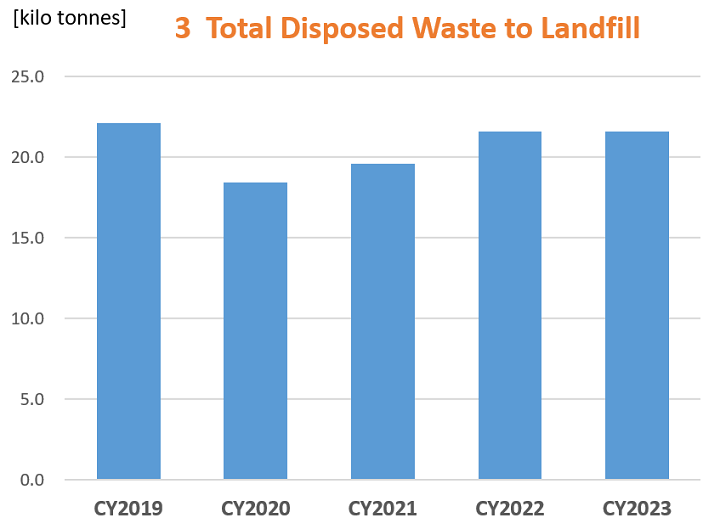

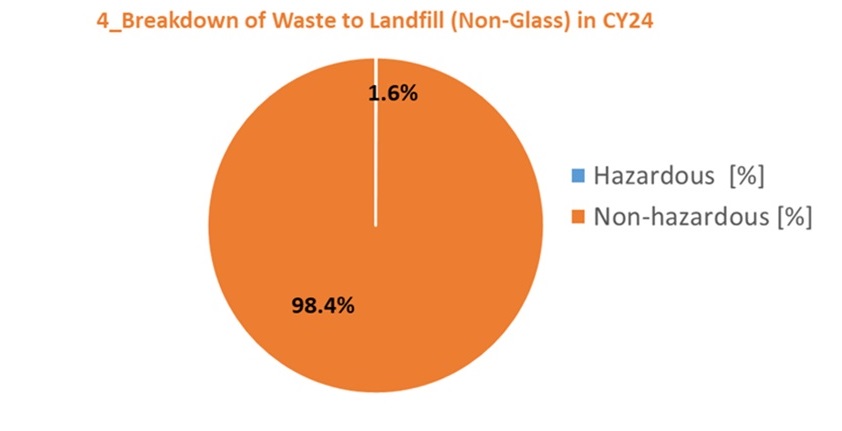

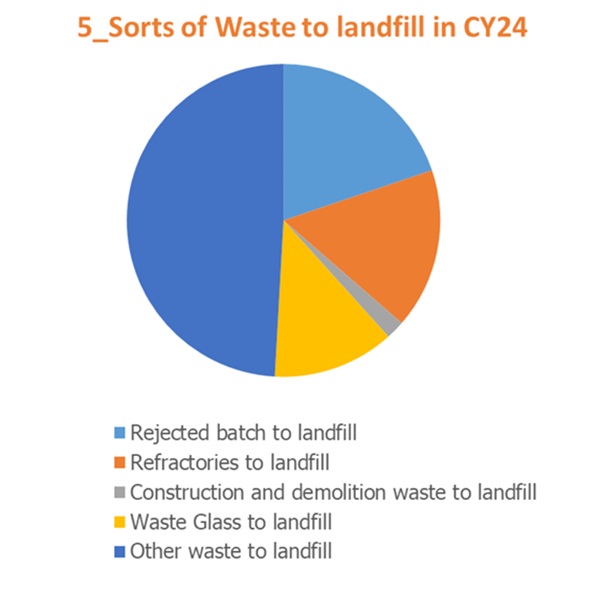

Waste sent to Landfill

In line with the tradition and commitment of the Sumitomo Group of Companies, the NSG Group is setting focus targets to reduce waste to landfill. Thus, because of the potentially significant negative impacts on the environment and human health and because the resources and materials contained in waste that is landfilled are lost to future use, which accelerates their depletion.

In former years the NSG Group reduced the waste sent to landfill by 50 percent up to 2013 versus the selected baseline year 2007 - and again by 16 percent until end of 2019 versus the baseline year 2014. NSG Group set a new Sustainability target to reduce this environmental impact by an additional 20 percent vs. FY24 by the end of FY2027. A small portion of glass cullet from Glass processing (3.4 kt in 2024 vs. 3.0 kt in 2023 ) is sent to landfill because of contamination – which is included in our Sustainability improvement target on waste to landfill and related activities.

The total waste to landfill in CY2024 has slightly increased to 22.4 kt (21.6kt in 2023), which was 3.7% increase compared to the previous year.

Efforts will continue to reduce this waste sent to landfill globally.

Third party waste management

Where possible, glass cullet from the manufacture of flat glass and downstream glass processing is reused back into the melting process under NSG supervision and management. Pre-consumer waste, either diverted from disposal or directed to disposal, is managed by third parties. All contracts with waste management and recycling partners are arranged with the imperative requirement to meet local environmental legislation and the NSG Group data reporting requirements.

In this regard - and as a pre-condition of the waste-service contract - the waste and recycling contractors are obliged to accept the NSG Group Supplier Code of Conduct and have to maintain certificates of their environmental and waste management qualification (ISO 14001 or equivalent).

Following a risk approach, additional audits were conducted by internal environmental experts in order to determine whether the waste/recycling contractor manages the waste in line with contractual or legislative obligations.

Other specific wastes

Grinding sludge

The waste stream from grinding of automotive glass edges and glass drilling cannot be prevented, but we have been actively seeking recycling partners to divert this waste from landfill and provide a raw material for concrete products and other aggregate manufacturers.

Float rejected raw material

In 2024, we continued to seek avoidance and/or recycling opportunities for glass dust and rejected batch materials - occasional off-specification raw material that often cannot be blended and some sorts of dust collected by the pollution abatement equipment.Floatr plants in North America recently found recycling partners for significant amounts of rejected raw materials.

General waste

Focus and support have been given to the highest volume producers to further improve general waste avoidance and segregation. Focus has been given to the avoidance and/or reuse of packaging materials. For the remaining sorts of general waste procurement has been actively involved in finding local recycling partners - rather than sending mixed general waste to landfill or incineration.

Wastes generated upstream or downstream in the value chain

Beside a few trials Post-consumer cullet is not currently used in the flat glass sector because the segregation of the end-of-life product (car/building/PV panel) does not lead to sufficient quality cullet. Its inert properties mean that it is currently used as an aggregate substitute. It does not emit hazardous chemicals or decompose to emit ghg at the end of life. However, NSG Group is committed to engaging with customers, architects and regulators to improve the circular economy of flat glass and ensure that it is sufficiently well segregated at the end of life to be re-melted as a raw material in the glass sector. The environmental impacts of waste from upstream suppliers is included as part of life cycle analysis studies.

7 Plastic Wastes emissions of NSG

Nippon Sheet Glass Co., Ltd. (NSG) is defined as "a high-volume emitting businesses" that emitted 250 tons or more in the previous fiscal year by the Plastic Resource Circulation Act in Japan.

Data collection from April to March in each year.

*1: Material or Chemical recycle

*2: Thermal recycling, disposal as RPF (Refuse derived paper and plastics densified Fuel), fuel to make cement, disposal through incineration to generate electricity or heat etc.