Water

Water utilization and Water management

In glassmaking, most water is used for cooling, and most of our plants operate with closed loop systems and so only require top up. Water is also used for washing glass in plants but there the need is for very high purity, so water is treated and then re-circulated. We seek to minimize our water consumption by working with suppliers to recycle water and to install advanced water treatment facilities. Processes are managed by Manufacturing Excellence's standardization procedures (e.g. turn off washer sprays when not needed, use optimal sized nozzles, install water catchers, implement controls to prevent overflows and maintain to prevent leaks, etc.). This not only reduces the withdrawal of water itself but also the chemicals used in the treatment of the water. Across the Group, water consumption can vary considerably according to process and product demands as well as water quality. Approximately 2.6m³ are required to manufacture one ton of float glass and approximately 0.12 cubic meters are required to process each square meter of automotive product.

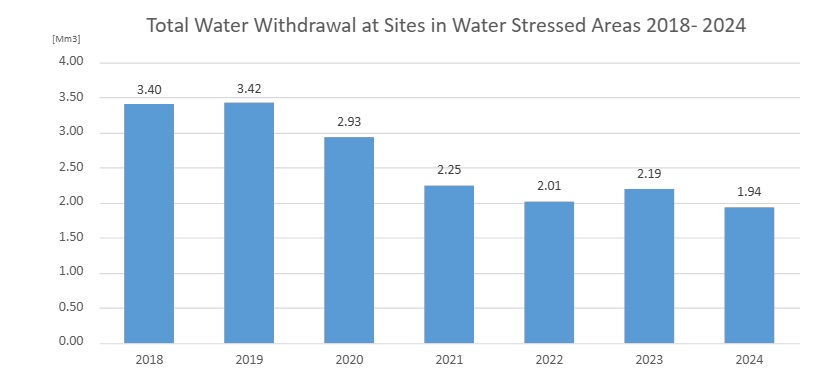

We withdrew a total of 1.9 million cubic meters of water in water stressed areas in FY2024/3. This is 43% reduction compared to 3.4 million cubic meters of water withdraw in FY2019/3.

Please refer to the "NSG Group Water Policy".

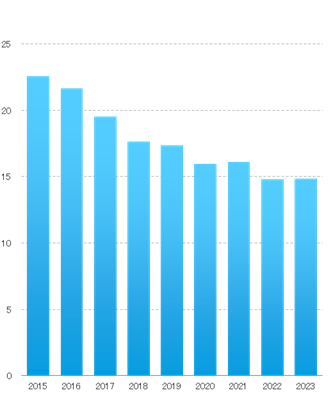

NSG Group total water withdrawal 2015-2024

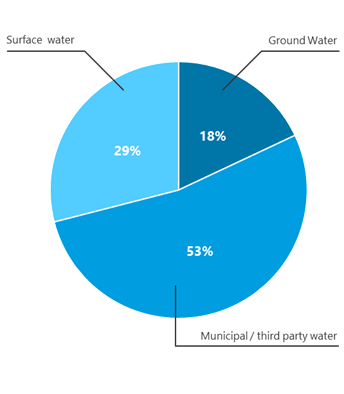

NSG Group Water withdrawal by source 2024

Please refer to the

data.

Water risks

We do not have any current stakeholder concerns regarding water scarcity or wastewater quality. On the other extreme of water risks, flood planning and prevention strategies have been applied where indicated. Water risks do not register as significant in the NSG Group risk assessment process; however, we will continue to risk assess all facilities. The NSG Group Sustainability Committee reviews risk and performance and discusses related activities on water management. The NSG Group has implemented an extra Water Policy in 2020 to ensure a clear statement of NSG Group's approach to water stewardship and in order to address water quality challenges and the risks of water scarcity in support of the Group Sustainability and Environmental Policies.

In 2019 the NSG Group implemented a new and more sophisticated Environmental Reporting and Analysis database. All sites are reporting their specific information and water data into this central database for further aggregation, analysis and monitoring on corporate and site level. Our up-to-date data reporting and reviews highlights that 10 NSG sites are located in water stressed areas in accordance with the global Aqueduct Water Risk Atlas. The water withdrawal at those sites represents 14% of the total in 2024. Those sites are subject to prioritized water management reviews and improvement activities in order to contribute to the global NSG Group target to reduce the water withdrawal at sites located in potentially water stressed areas by 50% by the end of the FY2027/3 versus FY2019.

At the NSG Group glass melting and Automotive Glass Manufacturing site at San Salvo, Italy, the plant management team is strongly engaged with the Water Council of the local community in order to manage water use and improvement activities. The San Salvo plant also implemented an emergency water supply management system and tested it during 2024.

In the last year, 450,000 cubic meters of water and 198 MWh of electricity were saved, generating an economic saving of 450,000 euros.

This is a virtuous trail, carried out by a cross-functional team, which brings clear benefits not only to the company but also to the local community, especially considering the water paucity that affects the area during the Summer.

This is based on employee awareness, water use efficiency, and a contingency plan in case of water scarcity scenarios. This project did win the Environmental Commendation Award of the NSG Group EHS Award in 2024.

And San Salvo plant also received the "Return on Environment Award" from Veolia, a partner company for water management and plant engineering services. The award identifies customers who exceed their environmental and operational goals while balancing productivity needs.

"Our water recovery starts here"

San Salvo team receives the "Return on Environment Award"

Water stress map - source: Aqueduct Water Risk Atlas

Water saving Projects

Beside the San Salvo Water projects and amongst other good water saving projects, another significant water saving project got implemented at a Float plant at Hanoi in Vietnam. This includes a system to collect rainwater plus water recycling at a glass washing machine - resulting in a ~17% reduction of the water demand at this plant.