"MAGNAVI™", High-Performance Fiber with High Modulus and Specific Strength

New Solution for the Growing Composite Market for a Sustainable Society

NSG Group is pleased to announce its newly developed MAGNAVI™, a high-modulus and high-strength glass fiber, that can be used as a new reinforcement1) for FRP and FRTP (fiber reinforced plastics). It has the highest level of mechanical properties available amongst all glass fibers, while keeping the radio-permeability and heat resistance that are inherent to glass fibers.

In recent years, the need has increased for lighter and thinner industrial products to reduce energy consumption. Based on this trend toward a shift from metals to composite materials2), MAGNAVI™ aims to provide a higher-grade solution in areas where conventional glass fibers or carbon fibers lack suitability. We have already started pre-production and will establish mass production capability at the Tsu Plant (Mie Prefecture, Japan) in the second half of 2022.

[Background of Development]

Due to the accelerated decarbonization trend, composite materials such as FRP and FRTP are being used as substitutes for metals in the field of industrial components. This growing demand for lighter and thinner products is helping to reduce energy consumption. Carbon fiber reinforcement has typically been used to improve the mechanical properties3) of composite materials, but its non-radio permeability, low heat resistance, high costs, and black colour make it unsuitable for some applications. On the other hand, glass fiber, which has also been used as a reinforcing component, has advantages in terms of colour selectivity, heat resistance and cost. It is also used for applications that require radio-permeability, but is inferior to carbon fiber in mechanical properties especially in rigidity. Therefore, development of a new higher performance reinforcing composite is needed as a replacement for conventional ones for FRP and FRTP, where applications are expanding.

[Product Features]

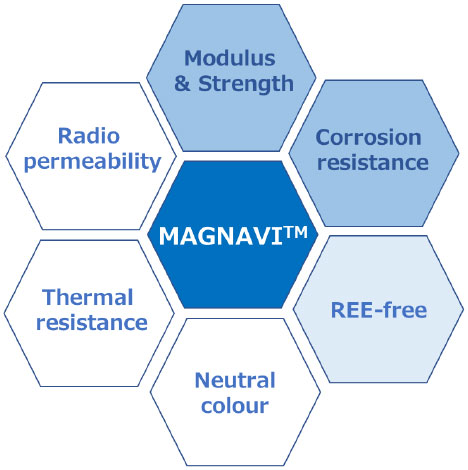

MAGNAVI™ has superior mechanical properties when compared to conventional glass fibers, in particular its impact strength is well beyond that of carbon fibers, while it also retains the inherent properties of glass such as neutral colour tones, electrical insulation and cost advantage. Therefore, MAGNAVI™ can be used in a wide range of fields, including electronics and renewable energy, where conventional carbon fiber is difficult to utilize. Advanced glass fiber sometimes contains rare-earth elements (REEs) to improve its elastic modulus. But these REEs are often considered to have a negative environmental impact with associated processing and procurement risks. MAGNAVI™ does not contain REEs in order to reduce these risks. Furthermore, "MAGNAVI™" contributes to the realization of a decarbonized society through an environmentally friendly production process by reducing energy consumption and CO2 emissions. For more details of MAGNAVI™, please refer to reference material (PDF).

[MAGNAVI™ Forms of Roving and Yarn]

[Features of MAGNAVI™]

■ Performance comparison with E-Glass (conventional glass fiber for FRP and FRTP)

MAGNAVI™ exhibits superior modulus and strength compared to conventional E-glass fiber.

MAGNAVI™ also has extremely high heat resistance compared to carbon fiber and aramid fiber, which are also used as reinforcement in composite materials.

■ Comparison of composite material properties with E-glass and carbon fiber added

When the reinforcing composites were added to the respective composite materials, MAGNAVI™ increased the strength and impact resistance and dramatically improved the mechanical performance of the components.

*Reinforcement fibers added to PA66 at 20%. The data sets are normalized to 100 for E glass composites. The indicated values are measured values and not intended for guarantee use.

[Application use of MAGNAVI™]

- Low Dielectric Constant8)/Electric Insulation×High Elasticity

MAGNAVI™ has the unique electrical insulation properties of glass fiber and higher mechanical properties than conventional glass fiber, making it suitable for a wide range of applications where electric insulation and high strength are required, notably in the field of electronics.

- Radome /UD components for electronic devices/ Lightweight & high-strength insulators for power devices/GFRP cases of the medium to large drones (incl. Central Plate)

- High Mechanical Properties×Neutral Color×Cost Advantage

Although MAGNAVI™ has a lower elastic modulus when compared to carbon fiber, its higher impact resistance, color selectivity and lower cost make it a practical alternative to carbon fiber in a wider variety of applications.

- Air cylinder/high-pressure gas containers/Hydrogen tanks for FCVs/Airplane interiors: flooring, walls in cargo rooms

- High Strength and Elasticity × Electrical Insulation × Corrosion Resistance

Insulators in the high voltage transmission segment are being replaced by plastic insulators instead of porcelain. These applications require light weight, high strength, and good insulation properties, which means that carbon fiber cannot be used and that the insulators must be acid resistant to avoid brittle fracture in acidic atmospheres. For these special applications, MAGNAVI™ can be the right solution.

- Polymer Insulators/GFRP Wire

[Explanation of Terms]

- Reinforcement: A material added to other materials in order to improve its properties such as strength or rigidity.

- Composite material: Composite materials are materials made from two or more constituents with significantly different physical or chemical properties, that when combined, produce a material with characteristics different from the individual components.

- Mechanical properties: A property that involves a relationship between stress and strain or a reaction to an applied force.

- Tensile modulus: Tensile modulus defines the strain levels at the maximum load thus the stiffness.

- Tensile strength: Tensile strength is amount of load per unit area the material can withstand axial load till it breaks.

- Flexural strength: The stress against bending calculated based on the maximum load that can be applied to a material when it is bent until it breaks.

- Impact resistance: A material's ability to withstand intense force or shock applied to it over a short period of time.

- Low dielectric constant: Dielectric constant is a quantity measuring the ability of a substance to store electrical energy in an electric field. The higher the dielectric constant, the harder it is to conduct electricity. The lower the dielectric constant, the easier it is to conduct electricity.

About the NSG Group (Nippon Sheet Glass Co., Ltd., and its group companies)

The NSG Group is the world's leading supplier of glass and glazing systems in the business areas of Architectural, Automotive and Creative Technology.

Architectural manufactures and supplies architectural glass as well as glass for the solar energy and other sectors.

Automotive serves the original equipment (OE) and aftermarket replacement (AGR) glazing markets.

Creative Technology comprises several discrete businesses, including lenses and light guides for printers and scanners, and specialty glass fiber products such as glass cord for timing belts and glass flake. https://www.nsg.com

The NSG Group's Medium-Term Vision

Under its Medium Term Vision, the NSG Group aims to be a global glass supplier contributing to the world with high value-added glass products and services and has identified the three areas to which it intends to contribute: "Safety & Comfort"; "Eco Society"; and "Information and Telecommunication". The Group will strive to achieve the Vision by supporting the development of information and telecommunication technology that can make people's lives more convenient and advance society, as well as by protecting the environment.

* The NSG Group's medium term management plan, Revival Plan 24 (RP24) (2022/3 - 2024/3)

https://www.nsg.com/-/media/nsg/site-content/ir/ir-presentations/mtprp24presentation2021_e02.pdf

MEDIA CONTACT:

Phone: +81-(0)3-5443-0100 or please use the contact form on the web

CUSTOMER CONTACT:

Business Development Department, Creative Technology SBU

Phone: +81-(0)59-238-1125 or please use the contact form on the web