Historically, the glassmaking industry has been insular and slow-moving. Knowledge was less likely to be shared and collaborative approaches were not common.

In the modern world, in addition to the challenges of climate change and globalization, the pace of development and changes in technology mean the historical way of working is no longer sustainable. Companies must be open to different perspectives, and quicker to react to the changing world. Consequently, NSG Group has been developing productive and collaborative partnerships with universities, tech start-ups, and key global business partners.

Examples of outcomes from these types of cooperative efforts are described here:

Royal College of Art

The Royal College of Art (RCA) is the world's most influential postgraduate institution of art and design. With the development of autonomous vehicles, different modes of working and living and the move from an owned economy to a shared economy there is a need to challenge the ways that our increasingly complex lives connect with each other and the world around us.

The recent 3 day NSG-RCA hackathon involving over 400 students challenged the role and opportunities for glass as a material, user experience and sustainability as we progress through the 21st century and the 4th Industrial Revolution.

PHYSEE

The relationship between NSG Group and PHYSEE is an excellent example of how large companies can work with scale-ups, engaging on multiple levels.

Initially work began locally in The Netherlands with research on digital sensors in the window manufacturing process and the interaction has since expanded to joint scientific research on advanced thin film coatings to maximize the benefit of solar energy.

Both companies continue to learn from each other during the collaboration – NSG Group benefitting from the perspective and innovative attitude of a tech scale-up, while PHYSEE gains insight into the operation of a global materials and manufacturing business.

PHYSEE was recently named the most innovative company in The Netherlands by the Dutch Chamber of Commerce.

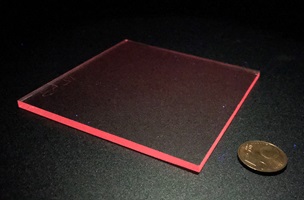

This solar cell equipped glass with an experimental luminescent coating re-emits light after being exposed to sunlight. The efficiency of this PHYSEE PowerWindow was made possible through collaboration between NSG Group R&D Scientists and PHYSEE.

University of Liverpool

NSG Group is engaged in a KCMC-led (Knowledge Centre for Materials Chemistry) partnership with representatives from the University of Liverpool, and the Hartree Centre. The cooperation aims at accelerating discovery of the next generation transparent conducting materials.

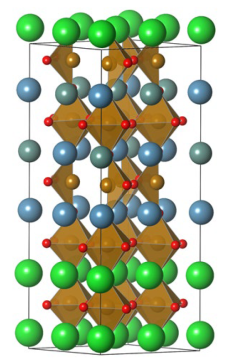

Using computational materials discovery and optimized supercomputing, we will expedite the rapid screening of new compositions. Materials that show promise will then be evaluated though experimentation and coating deposition to give a full analysis.

This KCMC-led partnership, supported by investment from EPSRC (Engineering and Physical Sciences Research Council) and STFC (Science & Technology Facilities Council), enables the partners to transfer expertise, key tools and techniques, and support academia working across the project.

Computational software generated an example of crystal structure for transparent conducting materials.

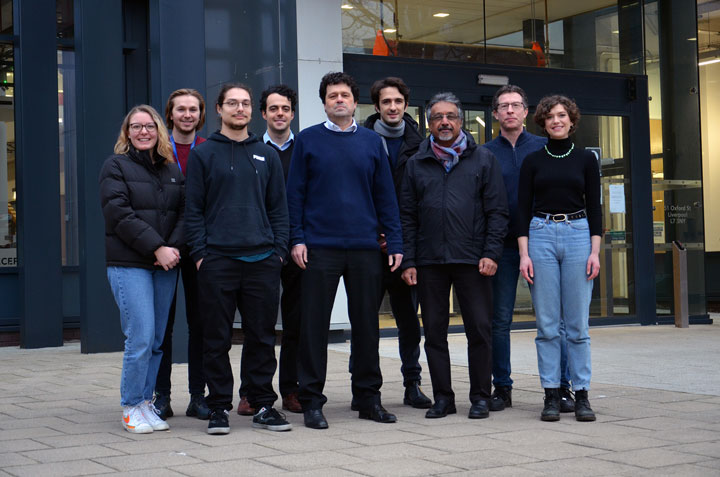

The NSG group supported PhD students at the Materials Innovation factory, University of Liverpool

Catherine Eagle, Tom Beesley, Luke Skilander, Rory Back (NSG R&D), Prof Matt Rosseinsky, Federico Ottomano, Dr Su Varma (NSG R&D), Dr Troy Manning and Anna Krowitz (From left to right)

Installation of Ubiquitous Energy’s UE Power™ window

NSG Group previously announced a joint development agreement between its subsidiary based in the US (Pilkington North America) and Ubiquitous Energy (UE), a leader in transparent solar technology, to jointly develop transparent solar windows in May 2019. The joint initiative has developed a fully transparent, energy-generating window featuring UE Power™, UE’s transparent photovoltaic technology.

A UE Power™ window was recently installed at the NSG facility in Northwood, Ohio. The NSG Group R&D team at Northwood played a vital role in the planning and installation and will also assist with ongoing monitoring. The installation takes a wide variety of technical data points from the site, such as wind speed, light exposure, and outside temperature.

NSG has a deep history in technology innovation and is very excited about the future of this BIPV technology, our partnership with Ubiquitous Energy, the benefits for customers and building occupants and the impact on meeting building demands of the next decade.

Click here to read more.